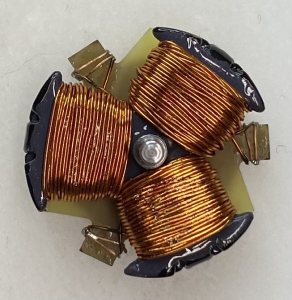

Phantom II (3.0 ohm, Double Wind)

Description:

This motor has two wires (Double Wind) wound in parallel and runs very cool. It is an easy to drive motor for those tracks that have lots of turns, but has stellar speed for long straights. Super fast in AFX cars.

Specifications:

- Resistance: 2.8 - 3.2 ohms

- Wind Type: Two Wire

- Balance: Yes/Epoxy

- Commutator Plate: Copper (Custom)

- Ignition Timing: Neutral, 7 degrees Advanced Only

- Pole Face Concentricity to Shaft: .000-.003"

- Shaft Welded: No

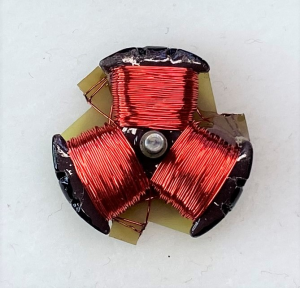

Description:

With neutral timing this motor is manageable for those tracks that have lots of turns, and has great speed for long straights. A Killer motor especially for AFX cars.

Specifications:

Resistance: 2.8 - 3.2 ohms

Wind Type: One Wire

Balance: Yes/Epoxy

Commutator Plate: Copper (Custom)

Ignition Timing: Neutral, 7 degrees Advanced Only

Pole Face Concentricity to Shaft: .000-.003"

Shaft Welded: No

Thunderbolt (5.5 ohm)

Description:

This motor is an easy to drive motor for those tracks that have lots of turns, but also has plenty of speed for long straights. This is also a good motor to add some speed to your AFX cars.

Specifications:

- Resistance: 5.2 - 5.6 ohms

- Wind Type: One Wire

- Balance: Yes/Epoxy

- Commutator Plate: Copper (Custom)

- Ignition Timing: Neutral, 7 degrees Advanced Only

- Pole Face Concentricity to Shaft: .000-.003"

- Shaft Welded: No

Spitfire (6.3 ohm)

Description:

This motor is an easy to drive motor for those tracks that have lots of turns, but also has plenty of speed for long straights. This is also a good motor to add some speed to your AFX cars.

Specifications:

- Resistance: 6.1 - 6.6 ohms

- Wind Type: One Wire

- Balance: Yes/Epoxy

- Commutator Plate: Copper (Custom)

- Ignition Timing: Neutral, 7 degrees Advanced Only

- Pole Face Concentricity to Shaft: .000-.003"

- Shaft Welded: No